Sail Drive vs Shaft Drive: A Detailed Comparison for Sailboat Owners

Choosing between a Sail-Drive and a Shaft-Drive system is one of the key decisions for boat builders and sailors alike. Both systems are responsible for transferring engine power to the propeller, but do so in fundamentally different ways. This article explores each system’s technical configuration, advantages, disadvantages, maintenance needs, safety concerns, and overall durability.

Overview

| Feature | Sail Drive | Shaft Drive |

|---|---|---|

| Introduced | ~1980s | Long-established, traditional |

| Typical Use | Production sailboats 25-50 ft | All types, including bluewater cruisers |

| Configuration | Pod-like system, integrated gearbox | Engine to prop shaft via gearbox, coupling, stuffing box |

What Are Sail Drives and Shaft Drives?

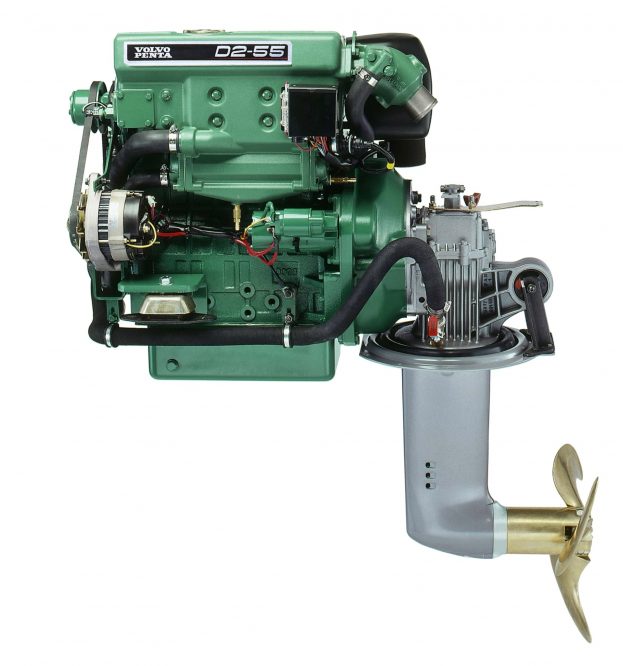

Sail Drive (SD)

The sail drive is a modern propulsion system introduced in the late 20th century, primarily seen in the production of cruising sailboats. It consists of a sealed pod extending vertically through the hull with an integrated gearbox and horizontal propeller shaft. Popularised by manufacturers like Volvo Penta and Yanmar, sail drives simplify engine-to-propeller connections and save interior space.

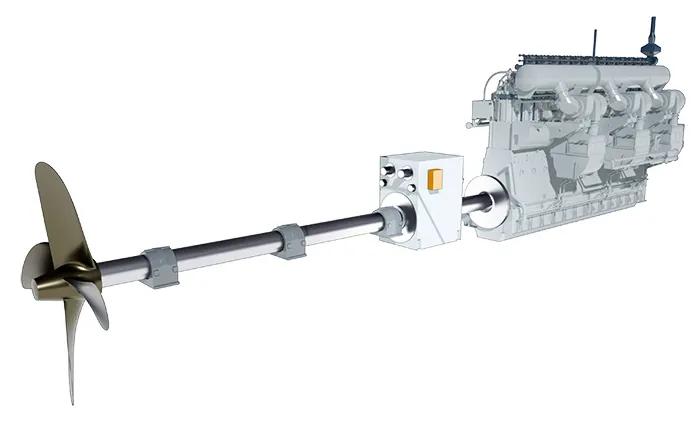

Shaft Drive (SDR)

The shaft drive is a traditional propulsion system on many sailboats, especially offshore cruisers. It involves a straight, horizontal shaft connected to the engine, passing through a stuffing box or dripless seal before reaching the propeller. Shaft drives have been the standard for over a century, valued for their simplicity and reliability.

Pros and Cons

Sail Drive

Pros:

Compact Design: Takes up less space in the engine room.

Lower Vibration: Better engine alignment and insulated mounts reduce noise and vibration.

Improved Efficiency: Horizontal propeller orientation offers better thrust and reverse performance.

Simplified Installation: Factory pre-assembled units are easier and quicker to install.

- The engine can be mounted further aft: This increases flexibility with the boat’s internal layout.

Cons:

Electrolysis Risk: Aluminium lower units are vulnerable in saltwater without proper bonding and anodes.

Seal Dependency: A critical rubber diaphragm keeps water out; failure can lead to flooding.

More Expensive Repairs: Replacing a damaged lower unit or worn seal can be costly.

Increased Fouling: Pod and propeller are more exposed to marine growth.

Shaft Drive

Pros:

Rugged Construction: Solid shaft and metal components offer high durability.

Field Repairable: Easier to service in remote or offshore conditions.

Lower Corrosion Risk: Typically uses stainless steel and bronze, which hold up well in seawater.

Cost-Effective: Fewer proprietary parts, cheaper maintenance and replacements.

Cons:

Alignment Sensitive: Misaligned shafts can cause vibration and wear.

Noisier Operation: Direct mechanical linkage transmits more engine noise and vibration.

Bulkier Layout: Requires more interior space and tighter engine alignment.

Less Reverse Efficiency: Propeller performance in reverse is often poorer compared to sail drives.

- The engine must be mounted further forward: This reduces layout options.

Safety Considerations

Sail Drive Safety:

The primary risk is the failure of the rubber sail drive seal, which typically must be replaced every 5–7 years. A compromised seal can allow water ingress.

Higher potential for galvanic corrosion due to aluminium components.

More exposed under the hull, it is vulnerable to groundings or debris strikes.

Shaft Drive Safety:

Shaft seals (stuffing box or dripless) can leak if not maintained, but are usually accessible for emergency repairs.

Less risk of catastrophic seal failure compared to sail drives.

More robust and less exposed to underwater impact.

Maintenance Requirements

Sail Drive:

Seal Replacement: Crucial diaphragm seal must be changed regularly (haul-out required).

Oil Changes: Lower unit oil is separate from engine oil; requires monitoring.

Anode Checks: Frequent inspection and replacement due to electrolysis risk.

Propeller Access: Requires diving or haul-out for service.

Shaft Drive:

Stuffing Box/Dripless Seal: Needs periodic tightening or replacement, but accessible while afloat.

Shaft Alignment: Should be checked annually to avoid wear.

Anodes: Easier to replace and monitor.

Easier DIY Repairs: Simpler tools and techniques can be used in remote locations.

Long-Term Durability

| Factor | Sail Drive | Shaft Drive |

|---|---|---|

| Lifespan | ~20–30 years (with seal maintenance) | 30–40+ years (with care) |

| Corrosion Resistance | Medium – vulnerable if bonding/anodes are neglected | High – bronze/stainless holds up well |

| Impact Tolerance | Lower – pod can crack/shear | Higher – shaft and strut are more robust |

| Parts Availability | Proprietary (brand-specific) | Standard marine components are widely available |

Practical Considerations

| Application | Recommended Drive |

|---|---|

| Weekend Coastal Sailing | Sail Drive – quiet, efficient, easy to install |

| Bluewater Cruising | Shaft Drive – durable, serviceable in remote areas |

| Performance Sailing | Sail Drive – better efficiency, less drag |

| Budget-Conscious Ownership | Shaft Drive – cheaper long-term maintenance |

| Charter Fleets | Sail Drive – consistent, easy to replace during haul-outs |

| Criteria | Sail Drive | Shaft Drive |

|---|---|---|

| Leak risk | Moderate – through-hull unit with rubber seals (needs regular inspection) | Moderate – stuffing box or dripless seal can fail |

| Electrolysis | High – aluminium lower unit must be well bonded | Lower – primarily stainless steel components |

| Emergency repairs | Harder – unit replacement not feasible at sea | Easier – many spares can be carried, field-serviceable |

| Collision vulnerability | More exposed under the hull | Shaft tucked inside hull, less exposed |

Maintenance

| Task | Sail Drive | Shaft Drive |

|---|---|---|

| Seal replacement | Every ~7 years (haul-out required) | Stuffing box or dripless seal inspection/replacement |

| Anodes | Must be checked often to prevent corrosion | Also required, but less critical |

| Alignment | Factory-aligned, usually stable | Needs periodic realignment |

| Oil change | Lower unit oil must be changed (often separate from engine oil) | Gearbox oil is typically shared or separate, but easy to access |

Durability

| Factor | Sail Drive | Shaft Drive |

|---|---|---|

| Lifespan | ~20–30 years with proper care | 30+ years with maintenance |

| Corrosion Resistance | Lower – due to aluminium and underwater exposure | Higher – stainless and bronze parts are more robust |

| Impact damage | Higher – can shear or crack | Lower – solid shaft is harder to damage |

Which to Choose?

| Sailing Type | Recommended System |

|---|---|

| Casual coastal cruising (newer boat) | Sail Drive – quieter, compact, easy to install |

| Bluewater cruising, remote repairs | Shaft Drive – rugged, simple to maintain offshore |

| Performance-focused sailing | Sail Drive – better prop efficiency |

| Budget-conscious ownership | Shaft Drive – fewer specialised parts, cheaper repairs |

To sum up…

Sail and shaft drives offer reliable propulsion solutions, but their suitability depends on the sailor’s priorities. Sail drives excel in comfort, efficiency, and ease of installation, making them ideal for modern cruising boats and coastal sailors. Shaft drives remain the gold standard for offshore and bluewater sailors seeking robust, repairable systems that stand the test of time.

Shaft drives are often the better investment for long-term ownership and remote sailing. Sail drives are a compelling choice for comfort, low vibration, and modern conveniences—keep up with the seal maintenance and bonding checks.

So when buying a boat, consider what you will be using it for and perhaps consider other choices like:

Author

-

Rene is a keelboat instructor and sailing coach in the Mandurah area WA. He is also the author of several books about sailing including "The Book of Maritime Idioms" and "Renaming your boat".

View all posts